|

|

12345

|

|

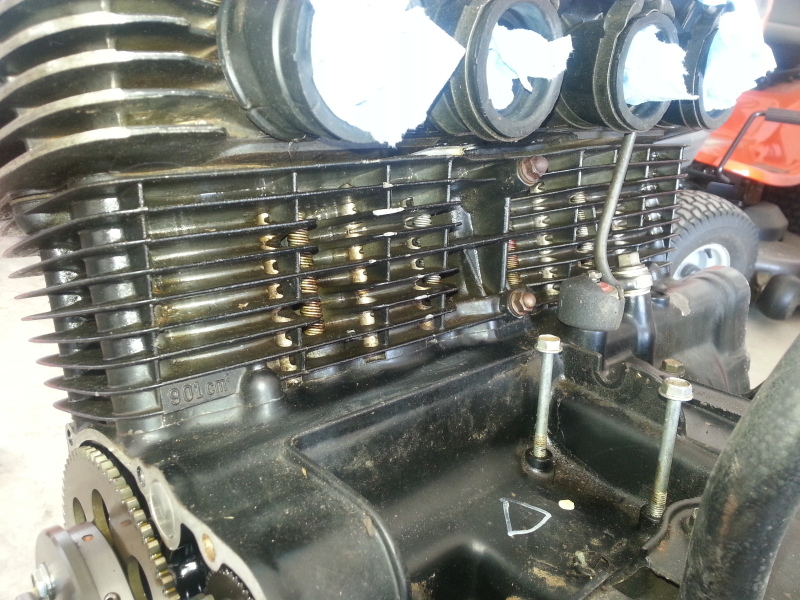

My spare engine came from a earlier bike, and has a oil cooler.

I haven't opened up the pan yet, but is it possible to delete this feature by swapping oil pans?

Or is the oil pump inside different and will require more modification?

It's very cool here, and I don't believe I'll need the cooler.

Any help is appreciated.

|

|

|

What bike is the engine from?

I don't know of a 750 that came with an oil cooler stock. Is it a 900 engine?

Oh, and welcome. I'm already stoked about this build.

1981 CB750K with 900 cams

90K KM's, rebuilt head, rebuilt carbs, upgraded valve stem seals

My wife's recipe website that I'm trying to help promote: Strawberries for supper. Yes, I am a lucky man.

|

|

|

This is the VIN on the is as follows:

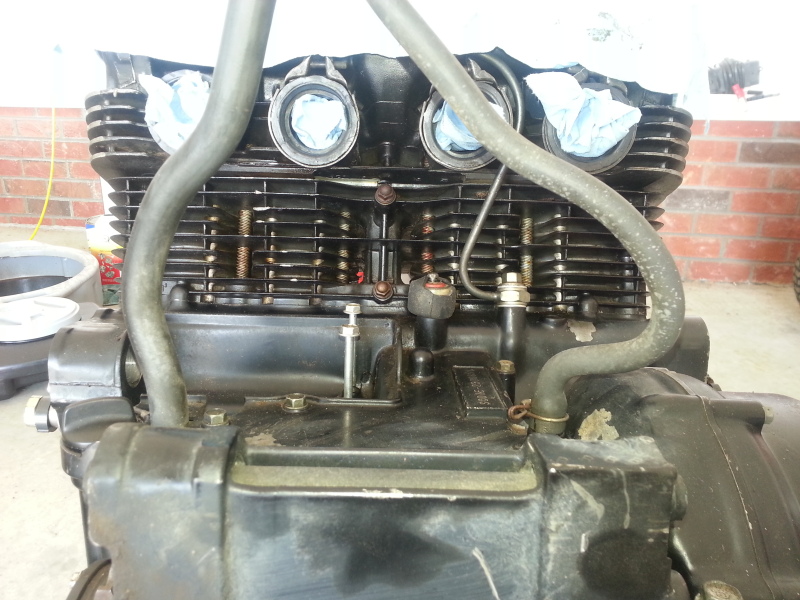

And here's the engine.

Maybe it is a 900... :D

|

|

|

Ya, that's a 900 engine. At least the cylinder and head are. On the 750c frame do the engine mounts look modified? The 900 engine fits in a 750 frame but requires modifications to the mounts to accommodate the rubber mounted engine and slightly different mount points.

1981 CB750K with 900 cams

90K KM's, rebuilt head, rebuilt carbs, upgraded valve stem seals

My wife's recipe website that I'm trying to help promote: Strawberries for supper. Yes, I am a lucky man.

|

|

|

Lemme tell you guys.

I've have had great success with DynoJet kits for my mikuni carbs on my GS750.

Now with this CB900, would anyone suggest I stay away for any reason?

The GS carbs didn't have adjustable needles, and the dynojet kit did.. and made it a lot easier.

Let me know your thoughts.

http://www.dynojet.com/pdf/1127.pdf

|

|

|

Hmm, I honestly don't know. I have read it is possible to graft a 900 cylinder and head onto a 750 lower, but I only know of one build where a guy tried and he hadn't gotten it to work yet.

Any chance the neck is grafted? Potentially dirty frame?

1981 CB750K with 900 cams

90K KM's, rebuilt head, rebuilt carbs, upgraded valve stem seals

My wife's recipe website that I'm trying to help promote: Strawberries for supper. Yes, I am a lucky man.

|

|

|

So maybe a CB750 rotating assembly, with 900cc pistons/rods and head?

I can also post up the SN of the case.

I think the frame is stock on this donor bike. I'll take another look though.

Wonder what nightmare I'm in for when trying to get this engine started. haha.

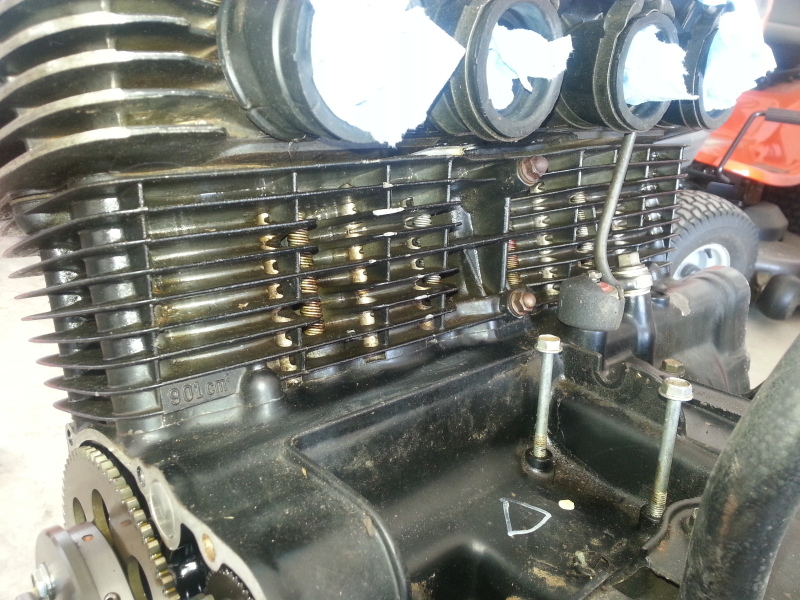

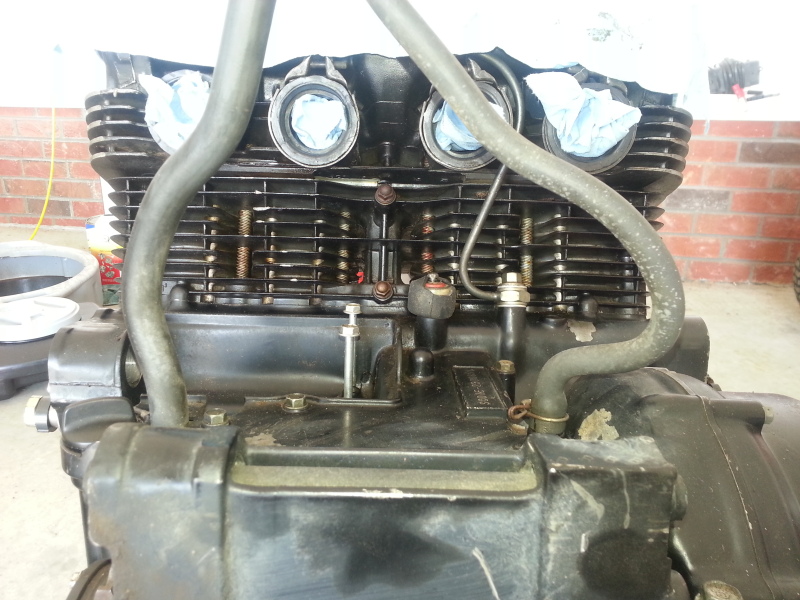

Here is a picture of the case:

And the frame it came out of, and no signs of frame mods:

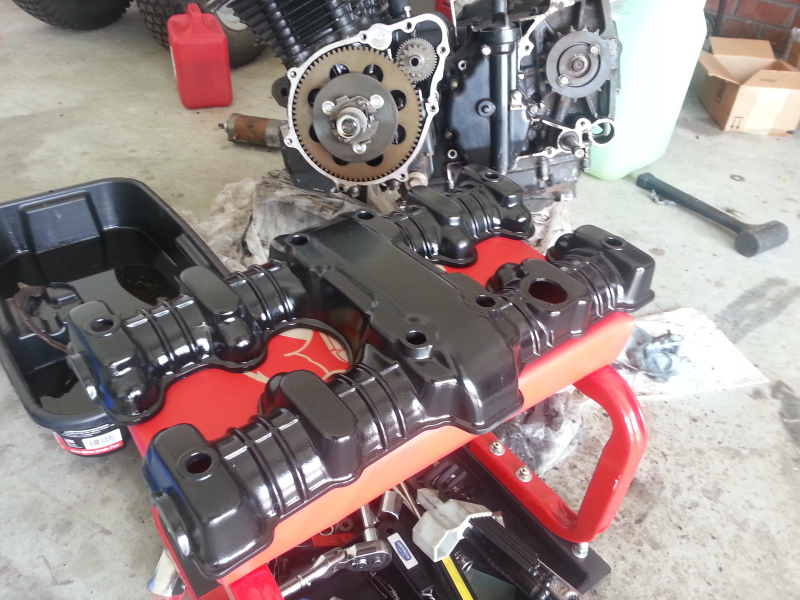

And here's the next frame it will go into:

|

|

|

Keeping up the momentum:

Stage 2 of cleaning the 900F tank.

I'm stripping the bits of paint on the underside.

Cleaning the rust the best I can, then I'll prime and paint it black.

The top side of the tank will be 2-tone black and bare steel polished.

I plan on designing the pattern to mask the polished area in CAD and print it on our stencil plotter.

Once I have the pattern, I can stick it to the tank [it's adhesive on the back side :-D ], then paint around it.

Should work out really nicely.

Here are a couple of more pics. (Sorry these are with my cell-phone, I have a much better rig for shooting photos but it's so much work to setup. Soon I'll take some really nice ones to share.)

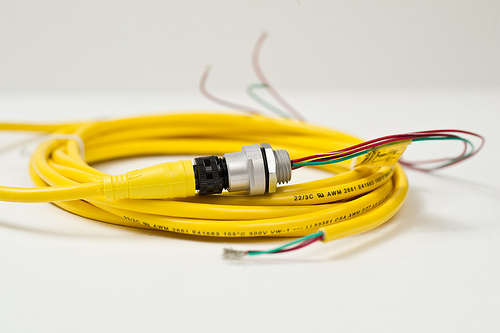

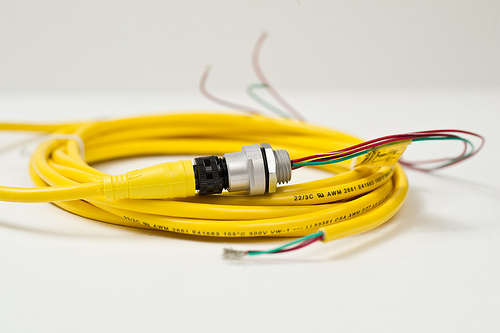

Also, below are some photos of the wiring components I plan on using.

Most are circular interconnects (amphenols.)

Previous owner of the 900cc engine did something retarded... but I got the cover off and scrapped it.

Here's my 750 engine cam cover:

And here it is again after I cleaned it up:

The bottom side of the tank before stripping/cleaning:

Some of the amphenols I will use:

|

|

|

That Cam cover looks amazing, good work on getting that cleaned up. Can't wait to see the tank when it's done and painted up.

|

|

|

Thanks, man.

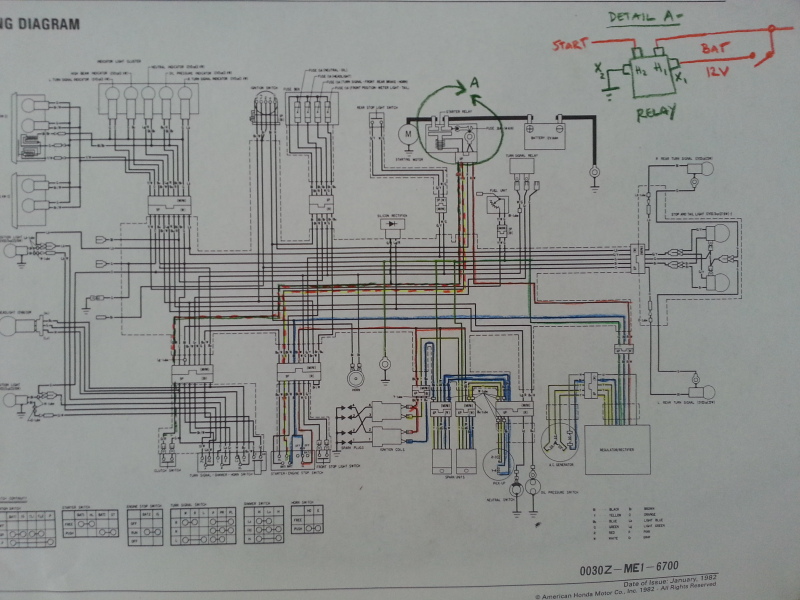

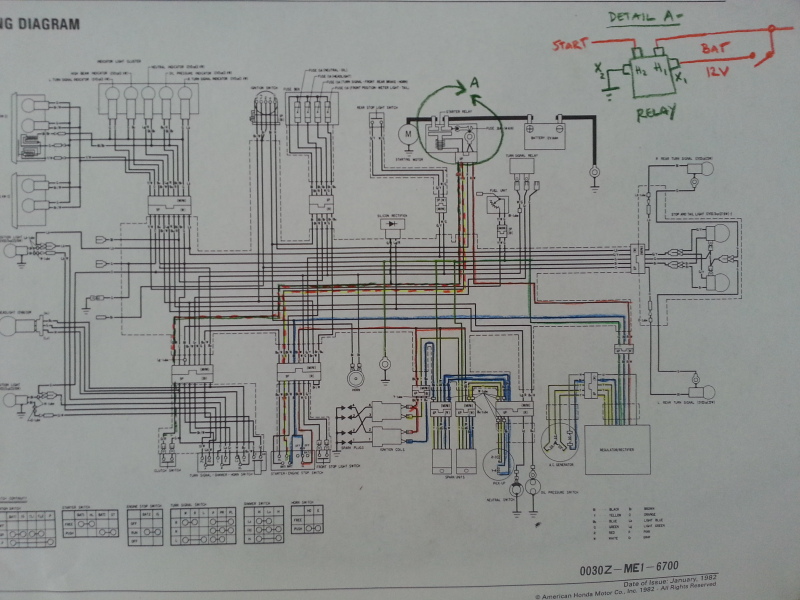

I plotted a 11x17" print of a wiring diagram, and started pinning out how I want to wire it.

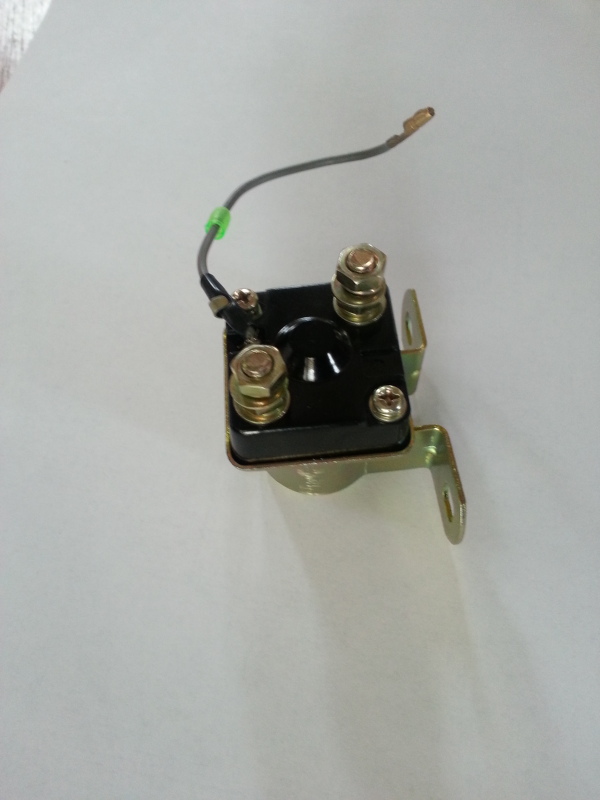

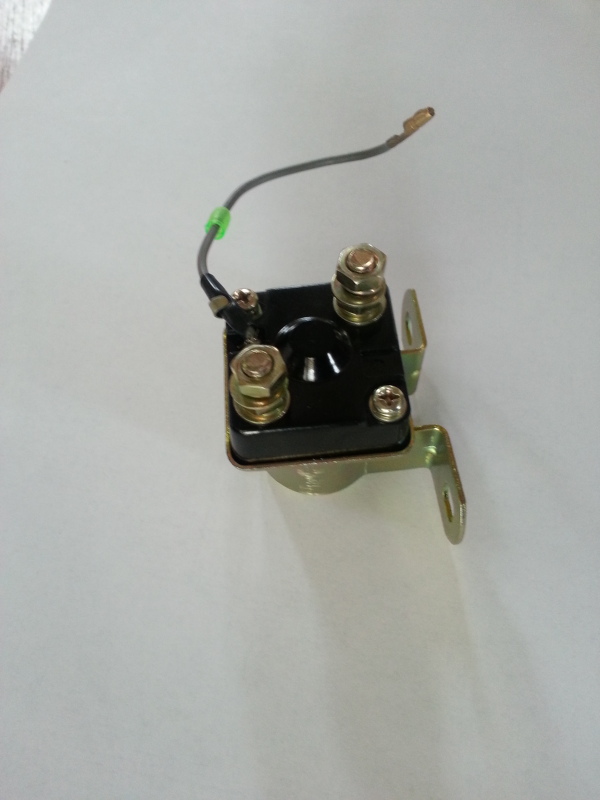

Also got my new starter relay. (The ones I had were fubar)

|

|

|

Getting the underside of the 900F tank cleaned up, prep it for primer, then a black enamel.

Couple pics:

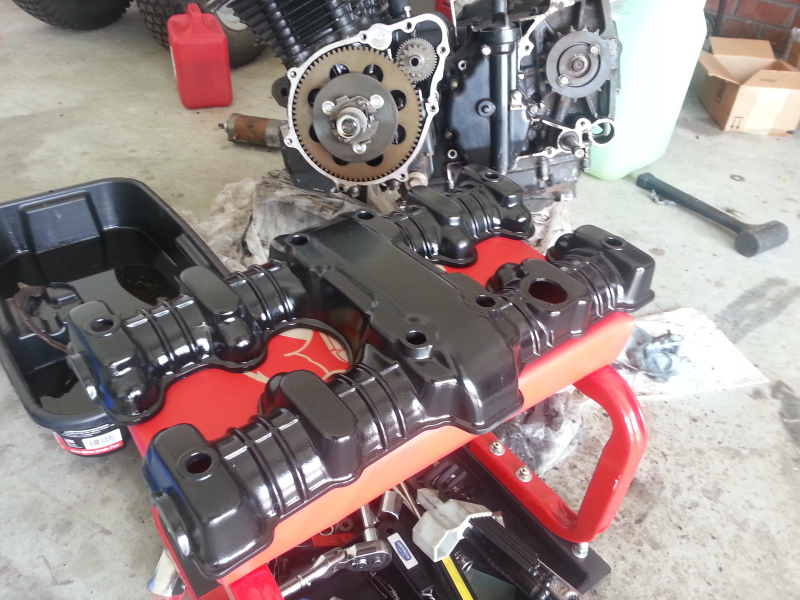

And the valve covers, will probably get another coat or 2 and then clear.

|

|

|

Here is some information on the CB750/900 oil cooling systems (I added a CB900 oil radiator to my CB750K, with a thermostat)...

The CB900 oil pan, and pump, can be bolted onto the CB750's. The CB900 has a dual-circuit oil pump: one circuit pumps oil, from the pan, directly to the engine; the other circuit sucks oil from the pan, and pumps it directly to the radiator, no thermostat, always pumping oil through the radiator, regardless of oil temperature... They have to be cold-blooded as hell -- that radiator sheds a lot of BTU's!

Your options are to install an OEM CB750 oil pan and pump, which will eliminate the radiator system, and return it to factory design. Secondly, you could install an oil thermostat, like I did, but you would still need to cover/mask the radiator in cooler temperatures (see below).

My 1979 CB750K had a maximum oil pressure of 72 PSI, at 7,000 RPM -- worm clamps won't hold that kind of pressure! Use T-bolt clamps: worked perfectly, all speeds, all loads (heavy saddlebags, with a passenger, at highway speeds). I took the CB900 radiator, cut the hoses, and I inserted an oil thermostat ( Perm-Cool Oil Thermostat): below 180 F, 90% of the oil bypasses the radiator, routed directly back to the engine; at 180 F, 95% of the oil goes to the radiator, with 5% bypassing it, returning directly to the engine. Below 60 F, the oil temperature never got above 180 F, so the radiator needed to be covered to get the oil up to minimum operating temperatures (180 F). The oil cooler kept the oil at 210-212 F, under all riding conditions and temperatures -- loved it! Oil ran at 250 F, sans cooler, which is the thermal limit of conventional oils -- also hard on seals, gaskets, rubber, etc.

Running the oil at 180-210 F, is far better than the OEM design of 250 F. Check your oil temperatures before you pull that cooling system: cover the radiator, and run it on the highway for 20-minutes (check oil temperatures by inserting a thermometer in the dip stick hole, if possible), note the air temperature; then uncover the radiator, and re-test, compare results to make an informed decision. The thermostat works well, except when the air temperature drops below 60 F. Installing an oil temperature gauge can help you run your engine at its best (install the sensor in place of the oil pressure idiot light's sensor, beneath the carbs, on top of the transmission), covering the radiator when necessary, uncovering it when the oil gets warmer. Just food for thought. Dropping the oil temperature from 250 F, to around 210 F, can double the life of the engine... Cheers!

1979 CB750K (sold, 2012, but not forgotten)

1983 Kawasaki 440 LTD Belt Drive (sold, 2011)

1993 Kawasaki Voyager XII

|

|

|

Thanks so much for that nugget of information.

Now knowing that the pump and pan out of my 750 may bolt up, it's something I may consider.

This isn't going to be my bike when it's done, and the rider (my girlfriend) will certainly not beat on any bike like I do. So, I will check the oil temperatures and see how it's performing.

I would worry about oil temperature getting up when it's 100% open all the time.

In that case, I'll definitely look into a thermostat and some hydraulic fittings.

|

|

|

With the T-bolt clamps, I used barbed hose fittings, from the plumbing section of my local hardware store. They worked, but I had to use hydraulic thread sealant, as Teflon Tape leaked, getting progressively worse over time. The special, AN fittings, or other hydraulic fittings, run the price up. Cheers!

1979 CB750K (sold, 2012, but not forgotten)

1983 Kawasaki 440 LTD Belt Drive (sold, 2011)

1993 Kawasaki Voyager XII

|

|

|

I'm considering the purchase of a soda blaster reservoir to use for parts cleaning.

At work, I have access to a sand blaster but I'd like something to use at home for engine cleaning.

There are a couple videos on YouTube of the kits I'm looking at and I am very impressed.

I think I'll stop by the Harbor Freight and see if they have the 15lbs version in stock.

I did degrease the 900 this weekend, but it's still in need of some TLC.

More pics to come.

|

|

|

Got a minty mint gas cap lock down strap! (with the key, so I'm excited about that.)

Couple pics of the engine before soda blasting.

I bought one of those self contained soda blasters, and it did a pretty good job... but MAN they're a mess.

I don't think I'll use it again though.

After soda blasting, I'm using some chemical strip to get all the little bits of paint left.

Haven't decided if I should paint it again, but if I do it will be black enamel and aluminum color enamel for the cooling fins.

|

|

|

Soda blasting is great, but it needs to be done either in a cabinet, or outside! It truly is a messy operation. Washing it away with water sounds easy, as well, but in my experience, the stuff gets everywhere, and it can take multiple washes, even under pressure, to get rid of the stuff. I found it inside springs, latches, and locks on my hard saddlebags, a year after I used it to remove surface rust from the latch mechanisms. I still like it, as it is a pretty fine abrasive, and it does an excellent job of removing surface rust (you really do have a fine level of control over how deep it goes). It just has its own set of drawback's. Cheers!

1979 CB750K (sold, 2012, but not forgotten)

1983 Kawasaki 440 LTD Belt Drive (sold, 2011)

1993 Kawasaki Voyager XII

|

12345

|