With those gauges you would still need to mount them on a board. Those long brass tubes would get broken off right at the threaded portion very easily because the brass is VERY thin. then you have a broken off brass part in the carb! They get broken ALL THE TIME!

Also all four of the gauges are not the same spring tension and would not get as good a result as a manometer type gauge.

That is why you do not see them used as much as the manometer type gauge.

Remember before syncing the carbs first you have to get all four gauges to read the same all hooked to #2 carb.

With those round spring operated gauges there is NO adjustment to get them to all be the same.

See photo below.

When you sync carbs it is the LAST thing you do in a tune up.

But before you can sync the carbs you need to get all four of the gauge levels to be the same while they are connected to #2 carb. This is explained in the instructions that come with the Motion Pro gauge manometer.

Then you hook the vacuum tubes to the other carbs to get all of the carbs syncronized.

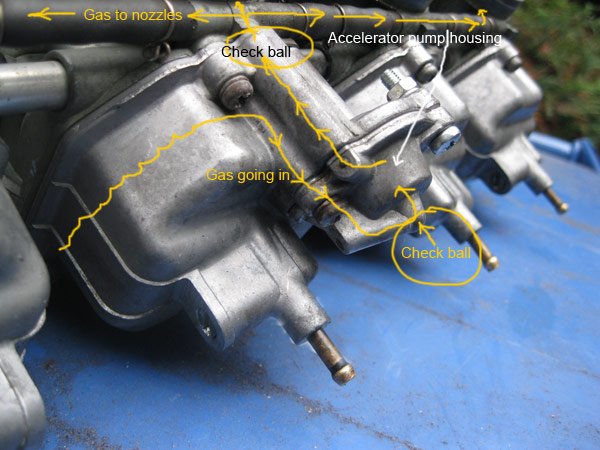

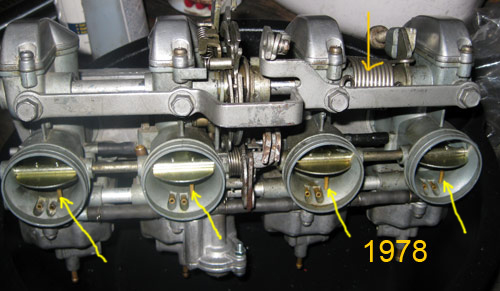

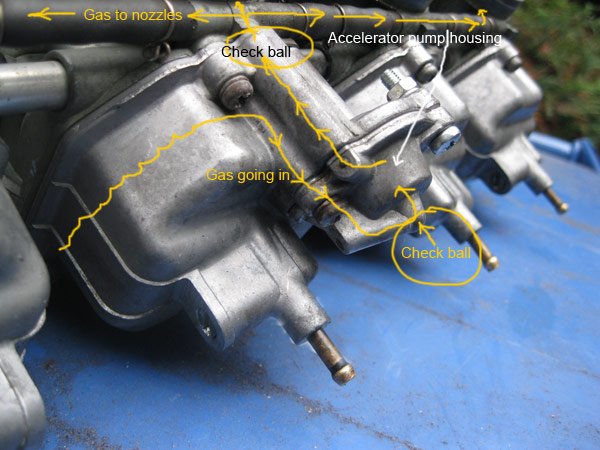

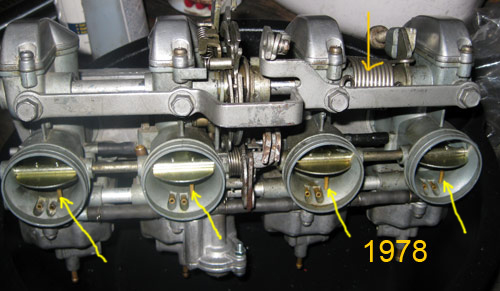

Also on that 1978 set of carbs (so called Keyhole style) they have an accelerator pump feature.

If that is NOT operating the carbs will not work right at all.

Look into the opening of the carb and you will see a small brass tube sticking up in each carb. When the throttle is advanced those little tubes spray gas into the engine. The gas sprays out the side of the tube NOT out the top of the tube.

If you just turn the throttle with the engine off and the gas turned on you should see ALL 4 of them squirt a stream of gas into the carbs.

If it does not work forget about syncing the carbs until you get that corrected and working properly.

The accelerator pump has two check valves with a steel spring loaded ball and the one in the bottom part is critical. If that part does not work right you can try to clean it but if it does not fix the problem then you will have to replace it. It costs $85.00 Fortunately I was able to get one.

Good thing too or I would have had to get one some other way or get a new set of carbs. There is no work around that I could think of.

The other check ball is in the top of the float bowl edge. IT does not usually get messed up as the bottom check valve because it can drain down but the bottom check valve ball is where dirt and water can collect and cause corrosion damage.

EDIT: July 2013.

After using the dial type vacuum gauges I would NEVER

go back to the fluid type gauges - too much trouble!

On a Roadstar Adventure.

I do not want it around my home/garage. I would not want my Grandchildren, or Toolmutts to get anywhere near it.

I do not want it around my home/garage. I would not want my Grandchildren, or Toolmutts to get anywhere near it.