I've had some time lately to work on my carburetors some more.

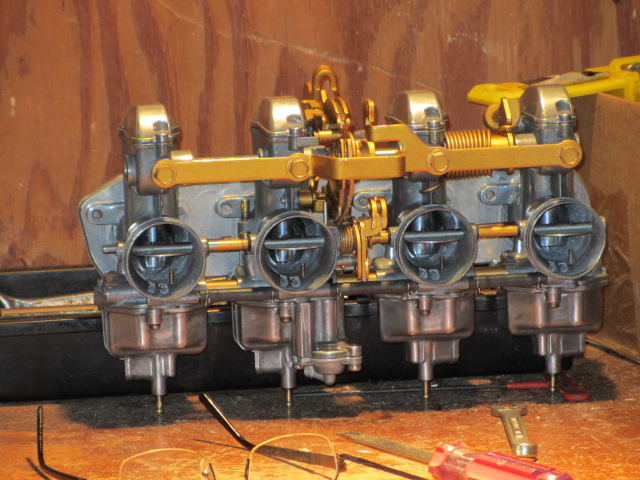

I took out my stock #35 pilot jets and replaced them with #42's for cooler idling. If I decide to open up my exhaust for more sound, I'll change the #110 mains out for #120's.

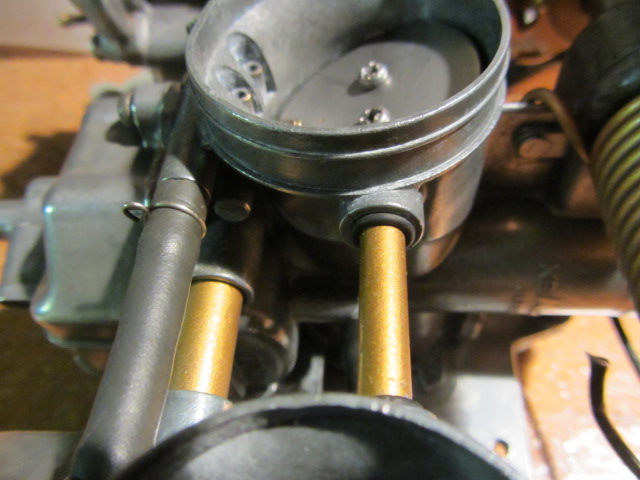

I don't know if anyone else has this problem but there are gaps between my choke shafts and the carburetor bodies that are pulling unfiltered air into the cylinder so I put some orings on the choke shafts next to each hole where the choke shaft goes through the carburetor to stop the leaks.

Installed a new accelerator pump.

Finally got all new parts installed, float levels set, float valves polished, new float needles, carbs put back together and bench sync'ed.

Got everything ready to do clear tube test, just have to figure out a way to make a temporary gas tank.

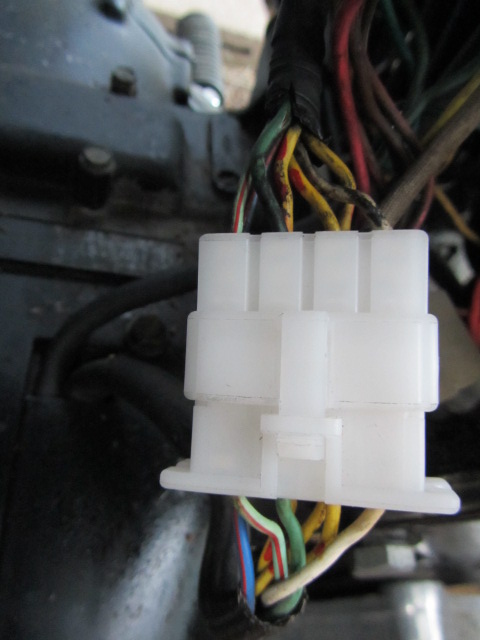

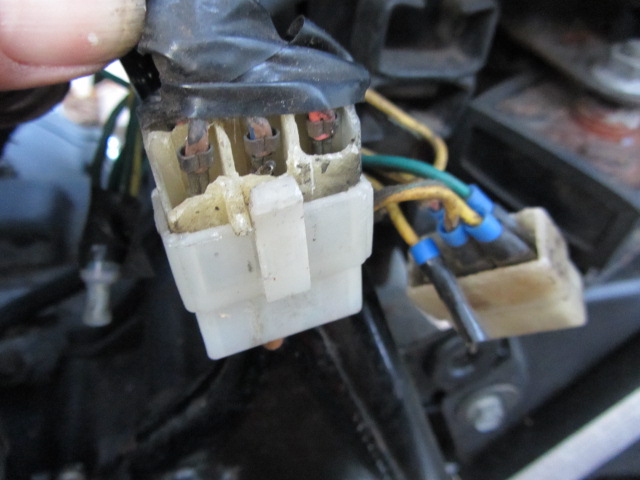

PO said it wasn't charging when he last parked it. Field and Stator coils checked out ok so this looks like it may be a weak link in the chain.

Lot of corrosion. Is there a way to seal these connector blocks to keep moisture out?

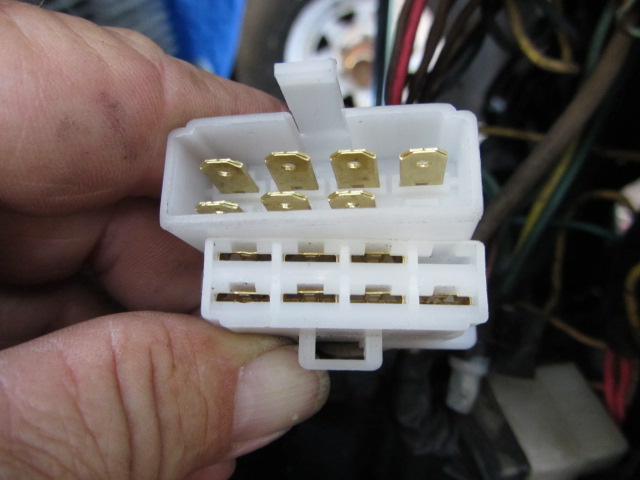

Cut old female connectors off and installed new ones, installing in connector block.

New male and female connectors installed in each half block.

Finished connector block

These other 2 6 wire blocks don't look so great either, think I'll replace them too. Is there a way to keep moisture out of wire connector blocks?

78 CB750F3 Super Sport

Austin, TX