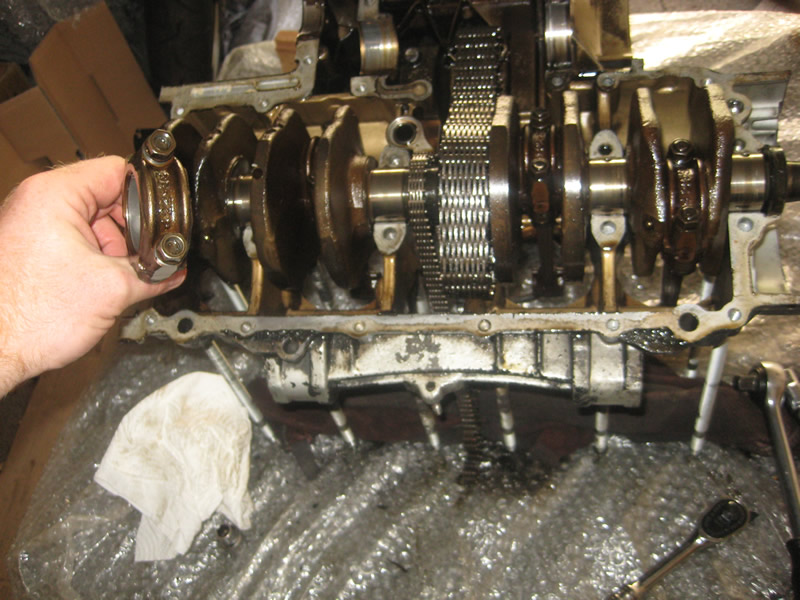

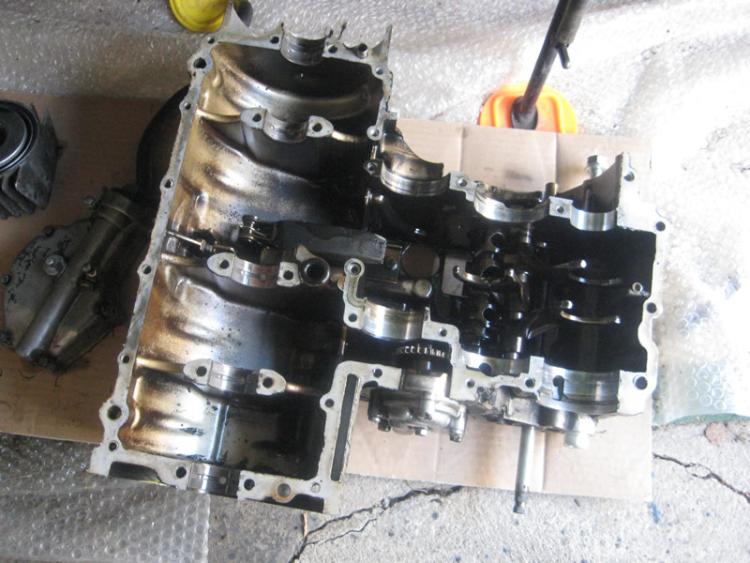

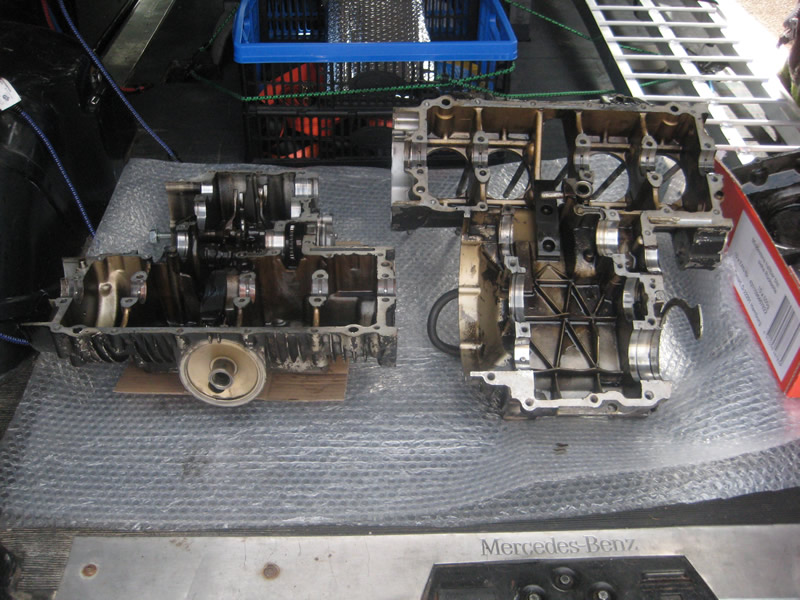

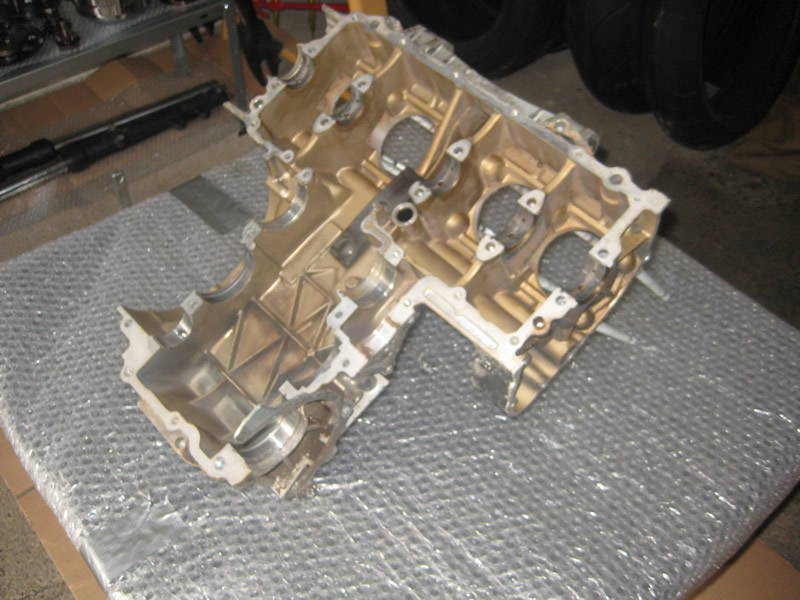

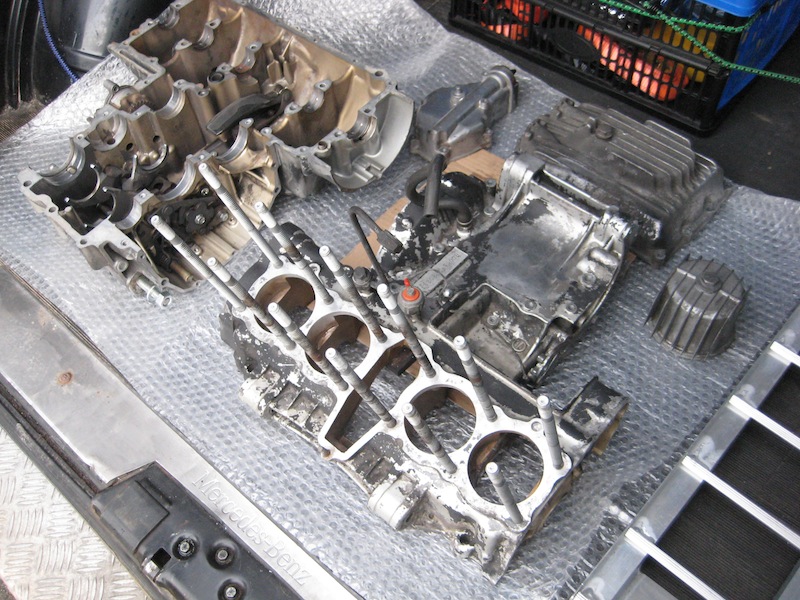

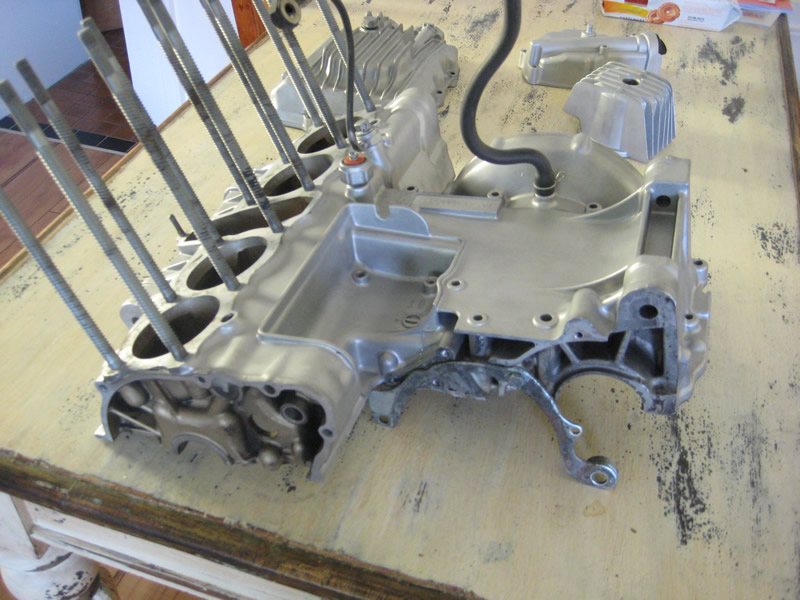

I think I have found a problem (if I have understood everything correctly) :

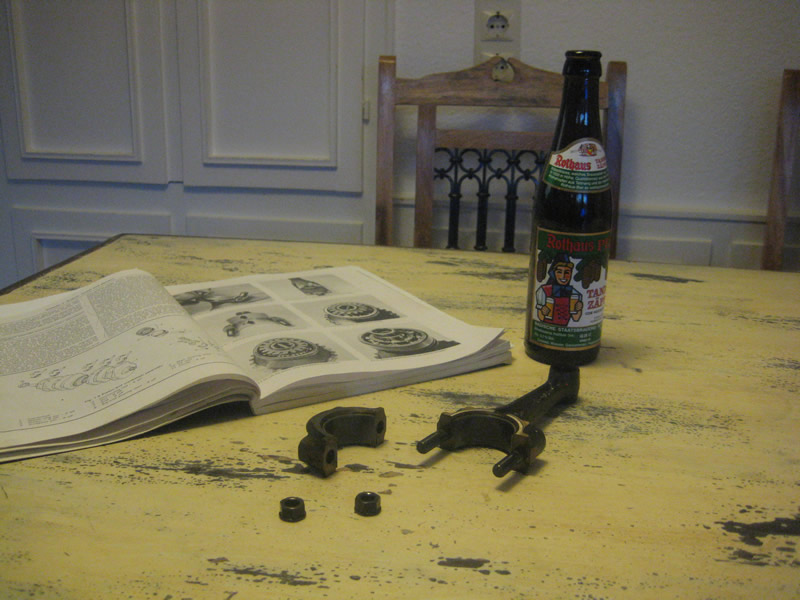

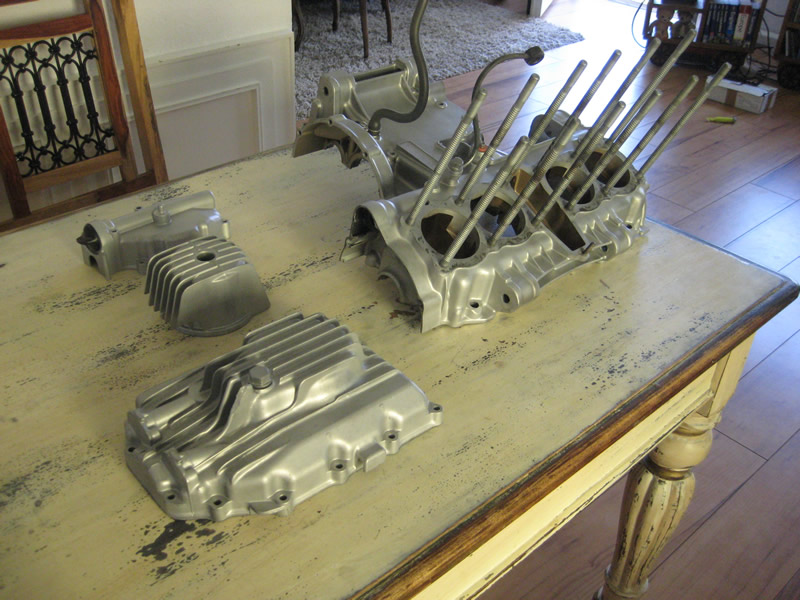

As I am waiting for parts (the parts I know need replacing ... ) to arrive, I decided to check the Primary Chain (according to the steps id the book :

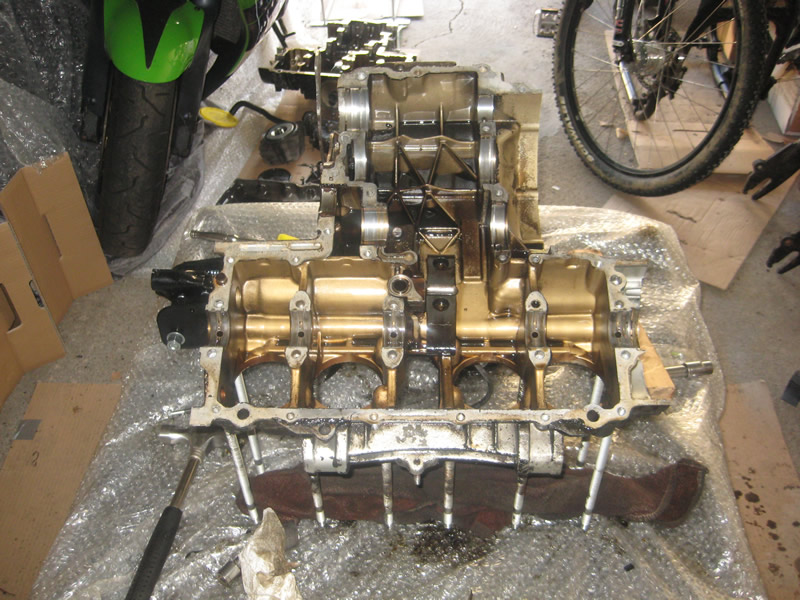

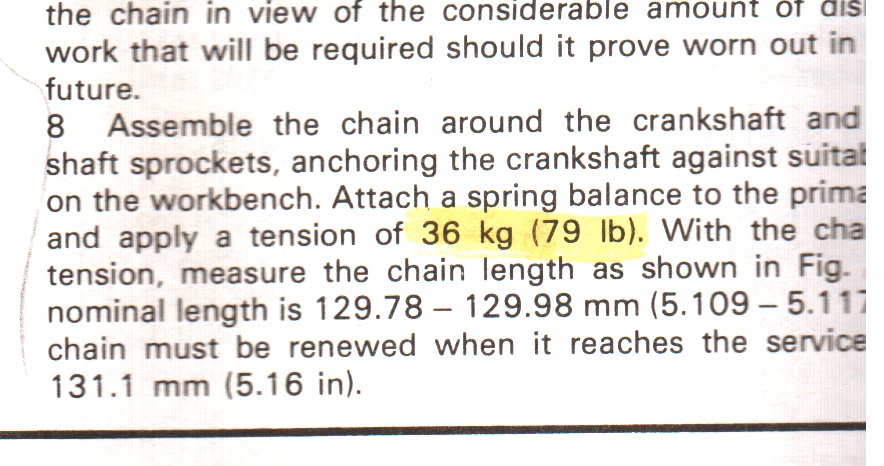

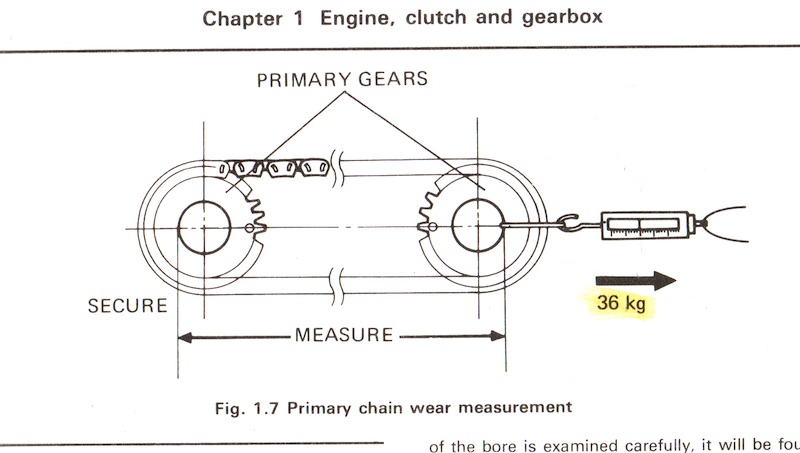

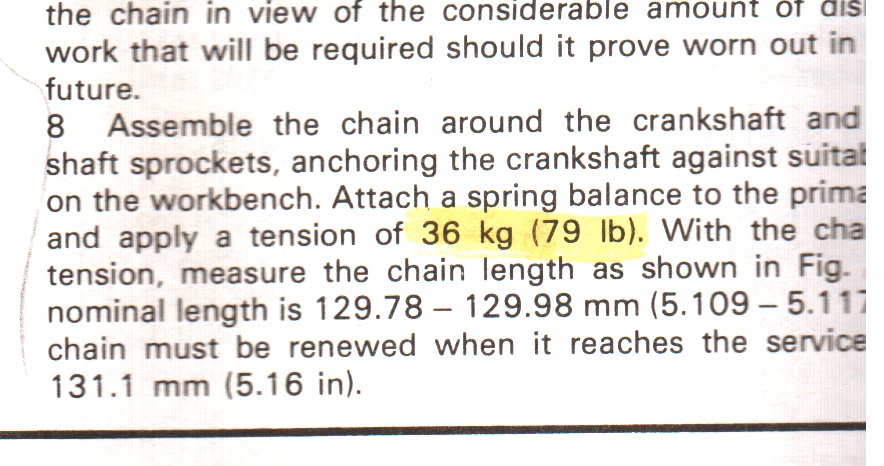

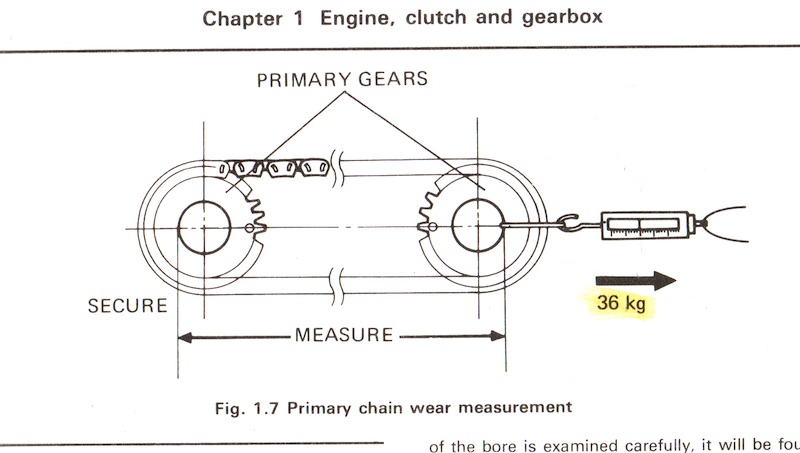

Sorry, I accidentally cut some of the text off during scanning and was too lazy to re-scan the page :( The text basically says to "[i]... assemble the chain around the crankshaft and primary shaft sprockets, anchoring the crankshaft against suitable stops ... and apply a tension of 36kg (79 lb) ... with the chain under tension, measure the chain length ... The nominal length is 129.87 - 129.98 mm (5.109 - 5.117 in) ... The chain must be renewed when it reaches the service limit of 131.1mm (5.16 in)[/i]" :

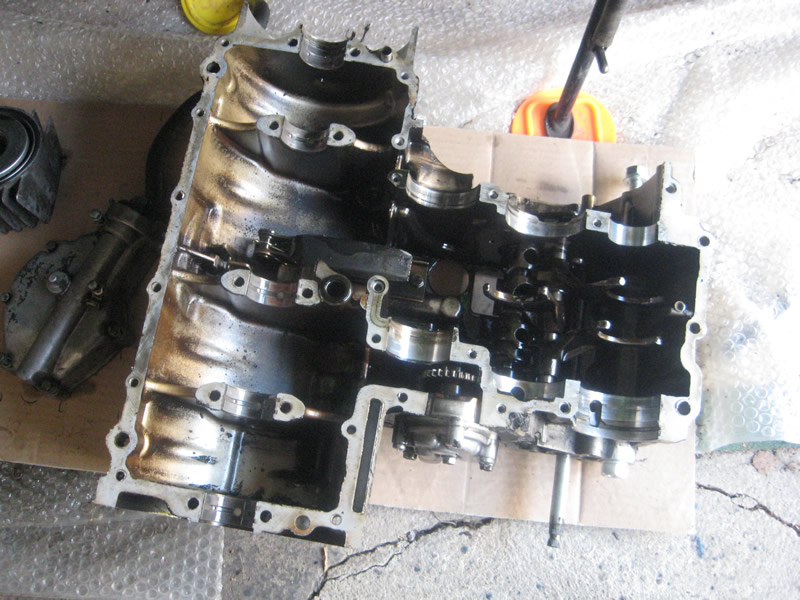

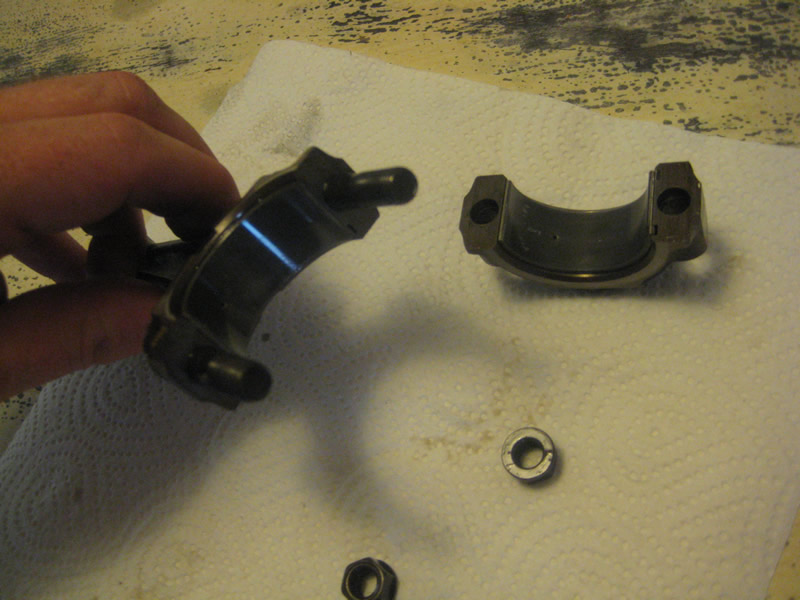

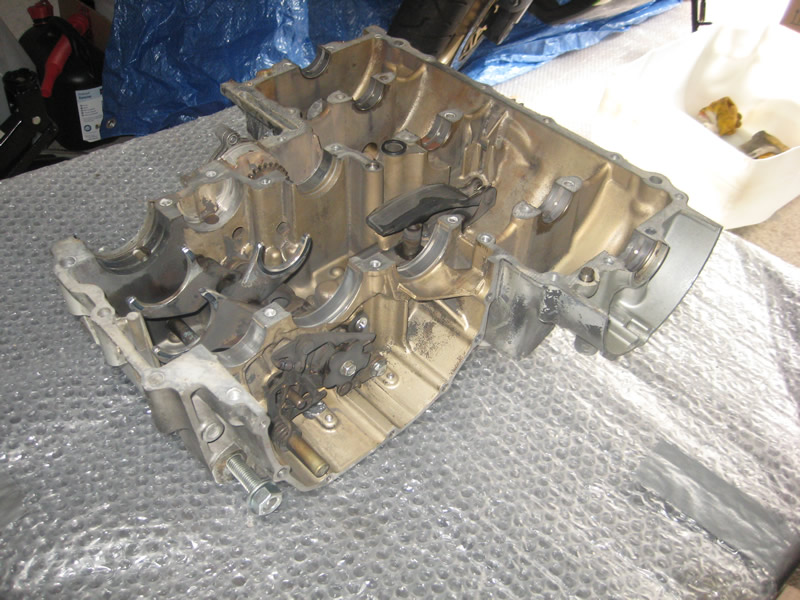

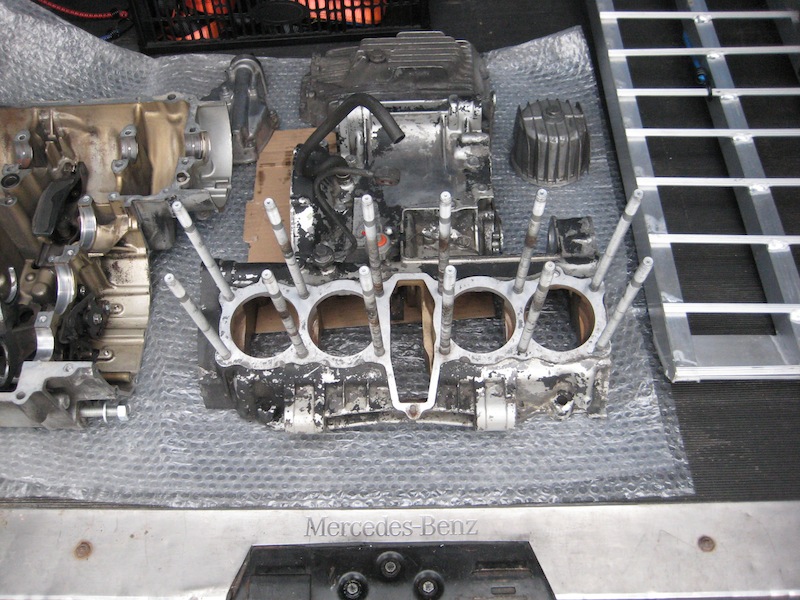

I am guessing looking at the pic (fig 1.7) I need to take the measurements form the outside of the 2 shafts ??? I was not sure, so measured from both the outsides of the shafts and inside of the chain (both of which were greater than the recommended renewal length of 1.31.1 mm (5.16 in)) :(

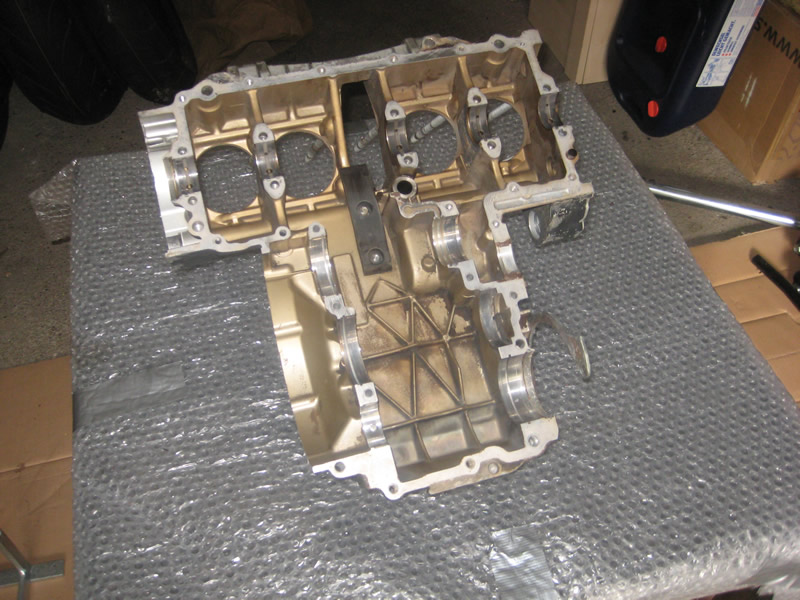

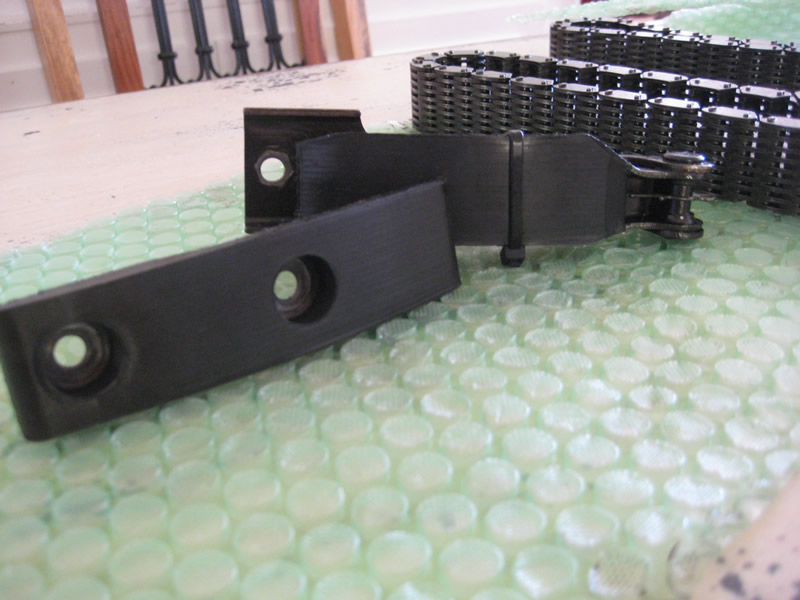

The chain did however look quite long in comparison to these figures what laid out in a rectangle (theoretically at the the shortest distances) - [b]Note[/b]: I know this is completely inaccurate and irrelevant in comparison to the figures etc... just thinking "out loud" ;)

[b]Anyway[/b]... onto some more accurate measurments:

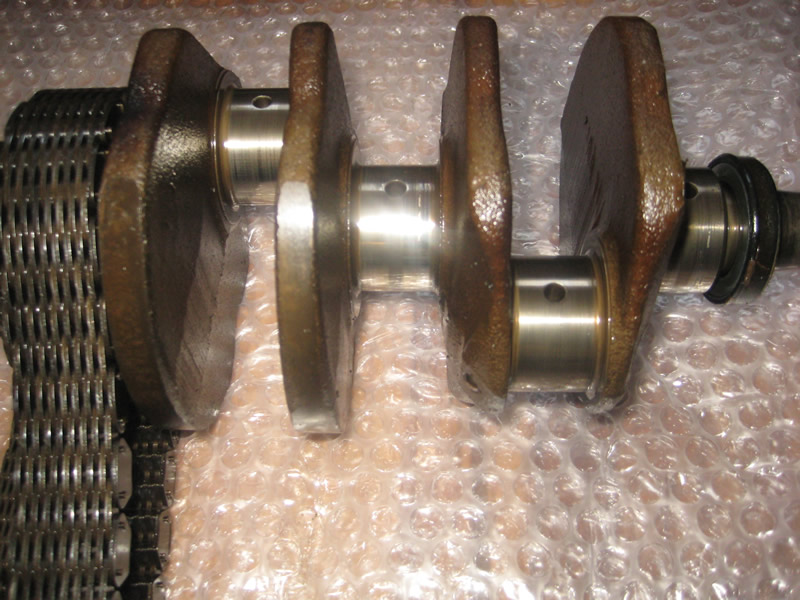

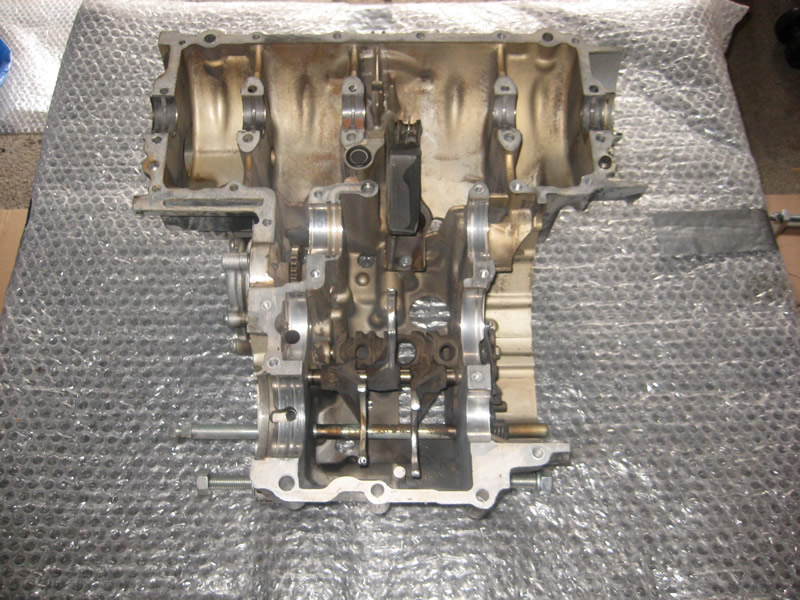

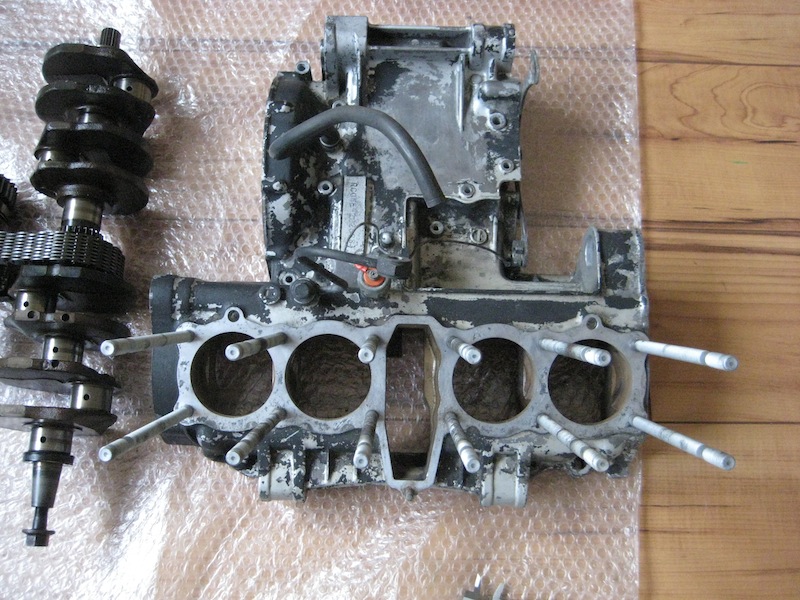

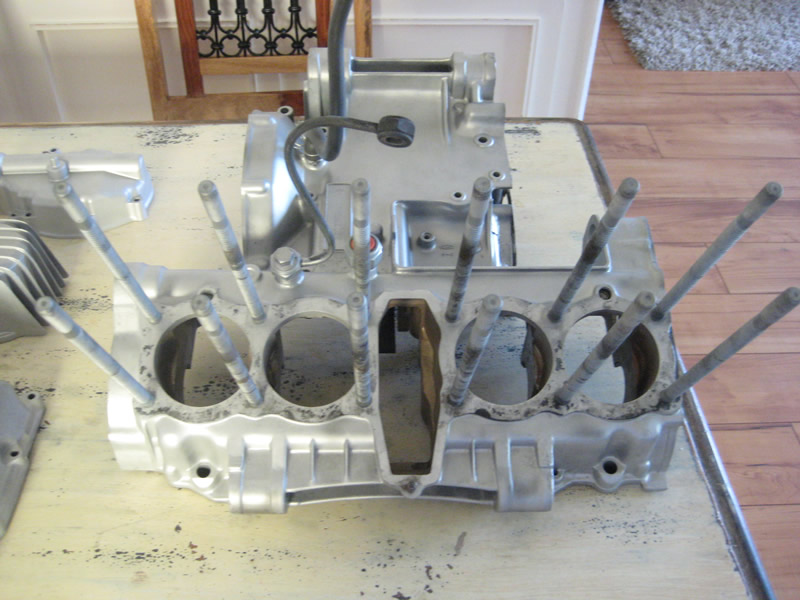

It was difficult to be 100% sure that te shafts were completely straight and supports in a stable / safe manner to prevent bending (not even sure if this is possible) or falling etc... but I did my best to get an accurate measurement...

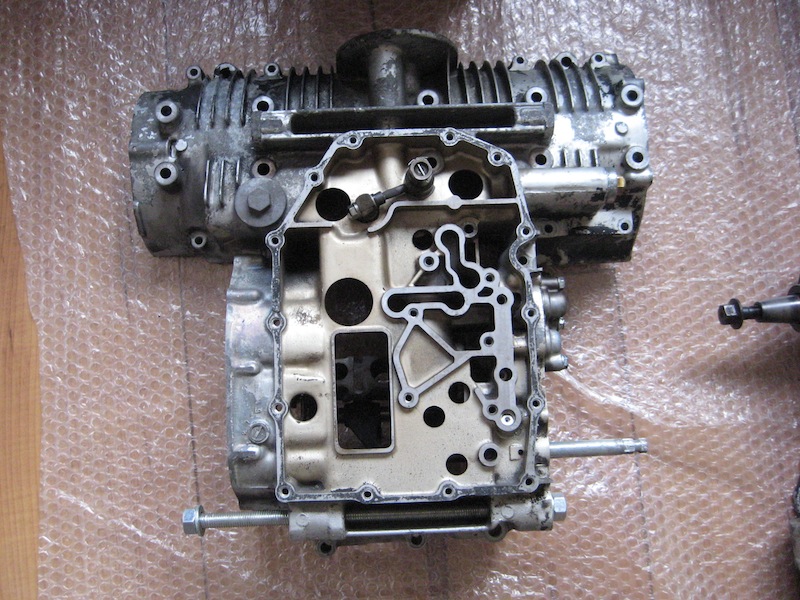

This picture it just to show where I took the measurements from (from what I understood from figure 1.7 above) :

Ok. So the length of the chain under tension, between the 2 points (outsides of the 2 shafts (top of cam shaft and bottom of primary shaft) was well over 130.1 mm - the reading was different each time, bot the average was more like 141.1 mm !!! with the measurements from the insides of the chain being even larger !!!

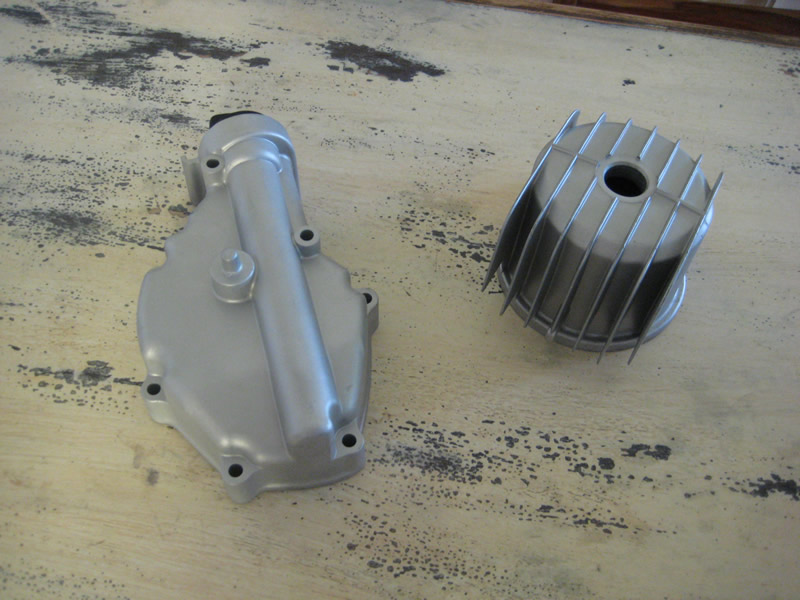

So a few questions arise (although I think I will play it safe and simply renew the chain)... :

1). Have I measured / tested this correctly ???

if so...

2). Im assuming the chain is knackered (is in desperate need of renewing) ???

3). Could this be the cause of the knocking noise when the motor was together and running ?

4). Could this explain why the primary chain tensioner is worn ?

5). What would cause a primary chain to be so worn - should I be worried ???

Further to this, I seem to be having trouble getting hold of both a primary chain and tensioner / guide from any local dealers as its not is stock and not available to order etc ... :(

Any suggestions / help again and as always is very much appreciated...