TOOLS1 wrote

I would have made them mount to the engine mounts; like Honda did with the matics,

and F models. Also I notice you have went back to the pods. Couldn't handle the wheelies?

TOOLS

This is an F model

lol.

The pods are on there because I'm a speed freak and I'm having to wait forever for my K&N filter to show. If I pull the air filter outta the airbox it runs like it means business. Still lacking the topend of the pods,but pretty stinking good. But the only filter I have is a greasy,gooey mess and I refuse to run with a filter. You see how funky my bike is

Gotta have filters.

I totally misled you guys on the frame flexing. Sorry!

The tube is not flexing as in bowing,it's twisting. The way I did the frame mounts they have a large welded area contacting the frame tubing,but they dont wrap around very far at all. They don't even wrap a 1/4 of the way around the tube. Kinda like the kickstand mounts: it's not just a flat edge welded to the bike,but it has a saddle,or a cuff, that fits to the frame so it wont try and twist the tubing at that area.The flexing is not severe.When you bang your feet on the pegs they feel rock solid. I even stood on them a bit during the test ride the other day. You can't feel them flex,but when you yank on the with your hand you can see them move. I'll just keep my eye on the weld seams and if I start to see a stress crack develop I'll reinforce it then.

Pulling off the engine mounts would definitely be a super strong mounting point. But I'd have to source some really long metric bolts which would difficult to find. And expensive. But it would also make for some very long brackets to reach back that far. That would be a lot of added weight and would bring up a whole other set of flexing issues. It'd take about 14'' to reach the engine mounts from where my plates are mounted now. 14'' of anything is gonna flex unless it super thick steel (

heavy) or heavily reinforced. <-Also,

heavy.

In other news...I got started on the levers. I got them mostly finished (still need a little filing) but I did get them welded to the pivots. The brake lever is shorter since I wanted it to hit the ball of my foot. The shifter I kept long so I wouldn't have to swing my foot out so far to swap from top to bottom on it. I have considered doing a two-tab shifter lever. Not a heel-toe,but where you would have a tab on either side of your foot at all times. Just rock your foot to shift without having to swap sides on the shifter. I can't decide if it would be a good idea or not,though.

I also found out that the knurled pegs hold dirt like crazy. The o-rings actually seem to provide a good deal of traction so I think I'm going to turn the knurls off and just run them smooth like this brake peg. Oh yeah,I got a brake peg done

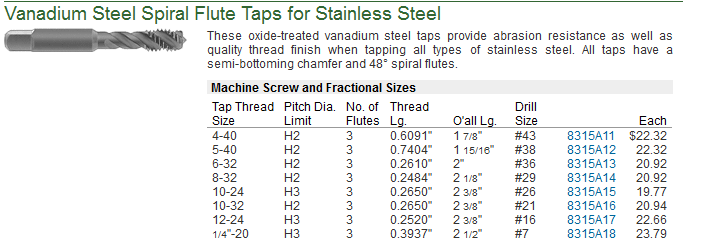

Looks much cleaner without the knurling IMO.I'm having trouble getting the stainless tapped,though. I just have a standard tap and die set,nothing heavy duty. I havent broke a tap off in this stainless yet,but I will if I try to go any deeper. I've only got about 3/8'' of thread inside the lever tab. I'd like to have at least 5/8-3/4''. I'm not sure what kind of tap I need to get or what is even available.

holy poo i just wrote a book ^^^

My apologies if you actually read all of that

What the...?!?! It's not my plates flexing. It's the actual tubing of the bike frame itself!!! I hope they dont stress crack the stinkin' frame. Still pondering on what to do there.

What the...?!?! It's not my plates flexing. It's the actual tubing of the bike frame itself!!! I hope they dont stress crack the stinkin' frame. Still pondering on what to do there.

lol.

lol.

Gotta have filters.

Gotta have filters.

I totally misled you guys on the frame flexing. Sorry!

I totally misled you guys on the frame flexing. Sorry!

Looks much cleaner without the knurling IMO.I'm having trouble getting the stainless tapped,though. I just have a standard tap and die set,nothing heavy duty. I havent broke a tap off in this stainless yet,but I will if I try to go any deeper. I've only got about 3/8'' of thread inside the lever tab. I'd like to have at least 5/8-3/4''. I'm not sure what kind of tap I need to get or what is even available.

Looks much cleaner without the knurling IMO.I'm having trouble getting the stainless tapped,though. I just have a standard tap and die set,nothing heavy duty. I havent broke a tap off in this stainless yet,but I will if I try to go any deeper. I've only got about 3/8'' of thread inside the lever tab. I'd like to have at least 5/8-3/4''. I'm not sure what kind of tap I need to get or what is even available.

My apologies if you actually read all of that

My apologies if you actually read all of that

Sadly,it broke just as quickly. The worse part is that it's permanently lodged in the piece it was supposed to tap soooo i got to start over on that.

Sadly,it broke just as quickly. The worse part is that it's permanently lodged in the piece it was supposed to tap soooo i got to start over on that. Zero progress this weekend on this.

Zero progress this weekend on this.

lol

lol

I'm so dumb,but don't tell anybody. Of course,I never made it anywhere near the bottom with this tap.

I'm so dumb,but don't tell anybody. Of course,I never made it anywhere near the bottom with this tap.